Blast Hoses & Fittings - Industrial Blast Hoses

Slide title

Write your caption hereButton

-

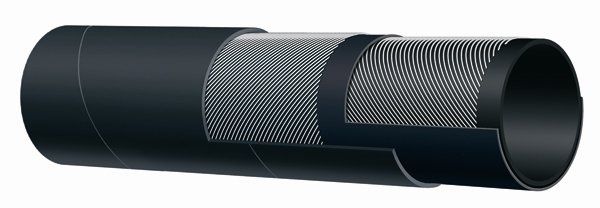

Industrial 4-Ply Blast Hose

Our 4-ply industrial blast hose is manufactured to conform to the most stringent industry standards. This hose possesses superior exterior and interior abrasion resistance allowing for long term usage under most conditions. In addition to its extended wear properties, the 4-ply reinforced construction allows for occasional contact by vehicle/forklift travel without collapsing the exterior tube. This hose is available with inside dimensions ranging from 3/4” – 2” and is packaged in either 50’ or 100’ sections. Custom hose sections can be made up to fit your specific application. All blast hoses come standard with static dissipating materials on the inner liner. The outside diameter of all our hoses is manufactured to accept all standard blast couplings and nozzle holders.

Slide title

Write your caption hereButton

-

Industrial 2-Ply Blast Hose

Our 2-ply industrial blast hose is manufactured to conform to the most stringent industry standards. This hose also possesses excellent exterior and interior abrasion resistance but is not designed for exposure to heavy machine or vehicle traffic. 2-ply hoses are available with inside dimensions ranging from 1/2” – 1-1/4” and is packaged in 50’sections. Custom hose sections can be made up to fit your specific application. All blast hoses come standard with static dissipating materials on the inner liner. The outside diameter of all our hoses is manufactured to accept all standard blast couplings and nozzle holders.

-

Clemco Supa™ Blast Hose

Clemco Supa hose was designed with ruggedness and flexibility in mind. When considering a blast hose for whip service, flexibility is often sacrificed for abrasion resistance when 4-ply hoses are used. As with other industrial blast hoses, the Clemco Supa hose features multi-layer fabric weaving for reinforcement but is designed with a thinner outer wall so that flexibility is maximized, and overall weight is significantly reduced when compared to a standard 2 or 4-ply blast hose. All Supa hoses come standard with static dissipating materials within the inner liner. This hose is available with 3/4″, 1” or 1-1/4” inside dimensions and comes packaged in 50’ sections.

-

Industrial Blast Hose Fittings - Blast Hose Crowsfeet

Blast hose crowsfeet are designed to screw on to the ends of standard OD blast hoses and interlock with each other to safely couple sections of hose. These fittings are universal in design and are manufactured in brass, aluminum and nylon alloys. Each fitting is tapped with safety holes that, once the fittings are locked in, will accommodate safety clips designed to prevent spontaneous fitting separation and operator injury. Nylon couplings come standard with integrated safety locks.

| Brass Fittings | Hose Size | Part Number |

|---|---|---|

| 1/2” ID | Q1/2B | |

| 3/4” ID | Q1B | |

| 1” | Q2B | |

| 1-1/4” | Q3B | |

| 1-1/2” | Q4B |

| Aluminum Fittings | Hose Size | Part Number |

|---|---|---|

| 1/2” ID | Q1/2A | |

| 3/4” ID | Q1A | |

| 1” | Q2A | |

| 1-1/4” | Q3A | |

| 1-1/2” | Q4A |

| Aluminum Fittings | Hose Size | Part Number |

|---|---|---|

| 3/4” ID | 08412 | |

| 1” | 21711 | |

| 1-1/4” | 08414 | |

| 1-1/2” | 07714 |

-

Blast Hose Nozzle Holders

Blast hose nozzle holders are designed to screw on to the end of a standard OD whip hose and are threaded to accept an industrial blast nozzle. Like their crowsfoot counterparts, these fittings are available in brass, aluminum and nylon alloys. Standard thread size on these fittings is 1-1/4” NPT however certain versions are available with 50mm contractor threads.

| Brass Fittings | Hose Size | Part Number |

|---|---|---|

| 1/2” ID | NH1/2B | |

| 3/4” ID | NH1B | |

| 1” | NH2B | |

| 1-1/4” | NH3B | |

| 1-1/2” | NH4B |

| Aluminum Fittings | Hose Size | Part Number |

|---|---|---|

| 1/2” ID | NH1/2A | |

| 3/4” ID | NH1A | |

| 1” | NH2A | |

| 1-1/4” | NH3A | |

| 1-1/2” | NH4A |

| Nylon Fittings | Hose Size | Part Number |

|---|---|---|

| 3/4” ID | 99173 | |

| 3/4” ID | 11398 (50 mm thread) | |

| 1” | 07721 | |

| 1” | 04127 (50mm thread) | |

| 1-1/4” | 07722 | |

| 1-1/4” | 04128 (50mm thread) |

-

Threaded Blast Hose Crowsfeet

The threaded version of the blast hose crowsfoot is designed to adapt to any sand valve or abrasive outlet and serves as the hookup point for the primary blast hose. These are available in brass, aluminum and nylon alloys and are also tapped to accommodate safety clips once aligned with another crowsfoot fitting. Nylon couplings come standard with integrated safety locks.

| Brass Fittings | Thread Size | Part Number |

|---|---|---|

| 1-1/4” | SB1B | |

| 1-1/2” | SB2B |

| Aluminum Fittings | Thread Size | Part Number |

|---|---|---|

| 1/2” | 00558 | |

| 1-1/4” | SB1A | |

| 1-1/2” | SB2B | |

| 2” | P32 |

| Nylon Fittings | Hose Size | Part Number |

|---|---|---|

| 3/4” ID | 99173 | |

| 3/4” ID | 11398 (50 mm thread) | |

| 1” | 07721 | |

| 1” | 04127 (50mm thread) | |

| 1-1/4” | 07722 | |

| 1-1/4” | 04128 (50mm thread) |

-

Full Port Blast Hose Couplings

Full port fittings are designed to provide the largest hole clearance between fittings therefore providing the least amount of restriction as material travels through the blast hose. These fittings are ideal for use with exceptionally long lengths of blast hose and in situations where material must travel vertically to the nozzle. By eliminating the “bottleneck” between standard fittings, a more consistent stream of abrasive can travel to the nozzle, reducing the pulsation and abrasive waste created during the starting and stopping of the blast process.

| Aluminum Fittings | Hose Size | Part Number |

|---|---|---|

| 1” | Q2X | |

| 1-1/4” | Q3X | |

| 1-1/2” | Q4X | |

| 2” | Q6X |

| Threaded Aluminum Fittings | Hose Size | Part Number |

|---|---|---|

| 1” | Q2X | |

| 1-1/4” | Q3X | |

| 1-1/2” | Q4X | |

| 2” | Q6X |

-

Blast Hose Fitting Gaskets

These gaskets are designed to seat two crowsfeet together and make a complete seal. With regular usage, these gaskets will wear and require replacement. Regular inspection of gasket wear and replacing them prior to total failure will ensure that the fittings last longer and perform better.

| Full Port Crowsfoot Gaskets | Material | Part Number |

|---|---|---|

| Rubber | SBG2X | |

-

Blast Hose Coupling Accessories - Safety Clips

Blast coupling safety clips are designed to fit into the pinhole slot machined into every standardized blast crowsfoot. Once the two fittings are aligned, the pinholes should match up and allow the safety clip to be inserted. Once installed, this clip will prevent premature uncoupling of the hose due to coupling or hose failure thus eliminating the possibility for operator injury. The option lanyard will allow the operator to secure the safety clip to the air fitting for easy retrieval when not actively engaged.

-

Blast Hose Safety Cable

When a hose separates under pressure, the two adjoining fittings can become projectiles causing serious injury or death. Blast and air hose safety cables (whip checks) are designed to keep two sections of hose bound together after coupling or hose failure, preventing them from whipping around as air escapes the line. When used in tandem with properly installed safety clips, these items serve as simple and effective means of eliminating potential worker injury on the blast site.

-

Blast Hose Coupling Screws

These heavy-duty tapping screws are designed to secure blast hose fittings to the hose once they are fixed in place. If a coupling is wears out or fails, it is ideal to replace the set screws along with the coupling. Most new blast hose fittings will include the necessary number of screws required to install however large packs are available for keeping spares on hand.

| Description | Package Qty | Part Number |

|---|---|---|

| Blast Hose Screws | 100 Screws/Bx | CS-1 |

Contact T-Tex Industries today with any questions and to begin your order.